Global Asset care partner with you to advance your Reliability digitalization efforts

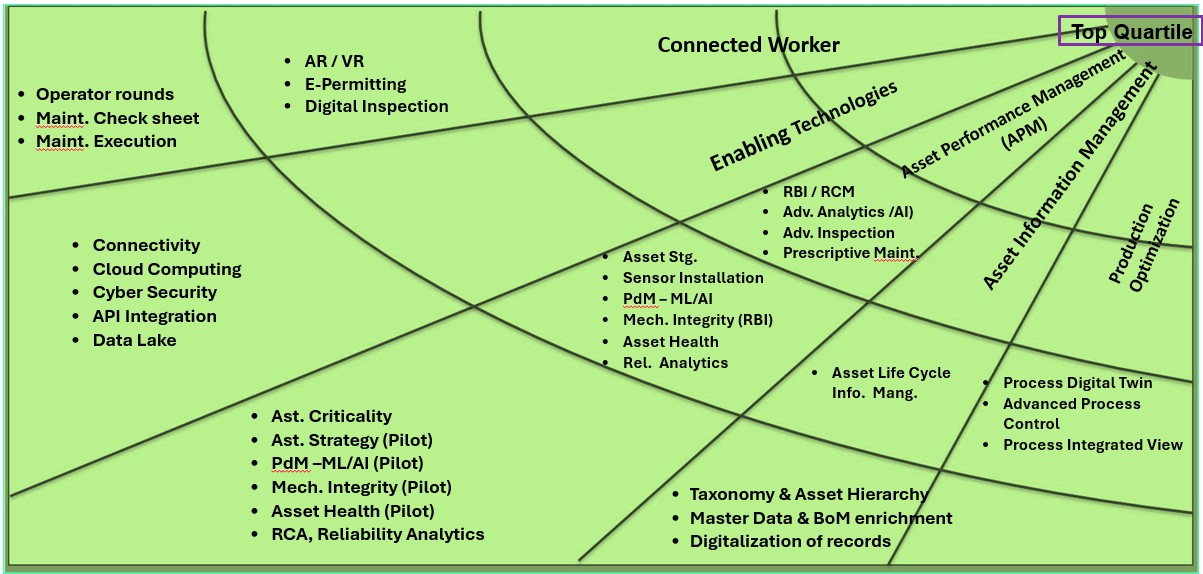

Digital transformation is a process in which companies implement technologies across their businesses to drive fundamental changes. The ‘Digitally Enabled Assets (DEA) can enable employees to improve personal and process safety, increase reliability and optimize cost performance of our assets.

By transforming the workforce with new competencies, and introducing new (business) processes, technology / tools, the DEA program can provide people with the reliable data that they need. With that, most value of the existing assets in terms of cost, reliability, and production can be achieved.

In collaboration with you (client) and OEM vendors, Global asset care is ensuring Digital Transformation solution meet your requirements and align with your vision. We bring expertise gained through working in one of the leading Canadian Oil & GAS integrated company.

We have firsthand experience in transforming business processes (simplification & standardization), evaluating, and selecting the right technology, converting ‘information’/document into quality data to enhance data-driven decision-making through advanced analytics (Machine Learning / AI), simplified governance structure focusing on sustainment at the outset of the project and finally transforming workforce of the future (THE PEOPLE).

Benefits

- Elevating our assets & people (creating an engaging, productive workforce)

- Improving business agility

- Creating efficiencies, improvements, and capabilities that were never imaginable or possible before.

- Unlocking of new value for employees, customers, and shareholders.

- Creating data driven values

Capabilities required

Today, most of employees working in the operation, maintenance and engineering/reliability lack the digital capabilities that are needed to make effective decisions to fully optimize asset performance.

A consistent approach is required to make data driven decisions by:

- building personnel competencies,

- applying all standards & business processes,

- providing access to right technology/tools and

Digital Transformation Operations maintenance Reliability Rev 4